Research Focus Test

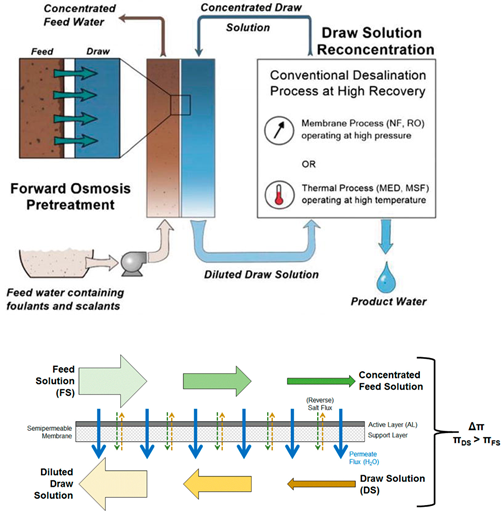

Forward osmosis

Forward osmosis (FO) is a membrane separation process. The principle of an FO process relies on using the natural osmotic process to draw the water molecules across a semi- permeable membrane from a lower concentrated solution or lower chemical potential (feed) to a higher concentrated solution or higher chemical potential, namely the draw solution (DS). FO has applications in separation processes for wastewater treatment, food processing, and seawater/brackish water desalination and also concurrent treatment of saline water and wastewater.

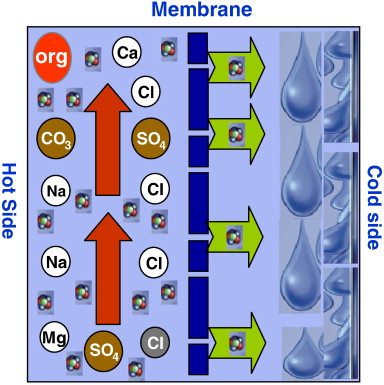

Membrane Distillation (MD)

MD is an emerging non isothermal membrane process for separation mainly suited for applications in which water is the major component present in the feed stream to be treated. This membrane process refers to a thermal driven transport of vapor through a microporous hydrophobic membrane, the driving force being the partial pressure difference between each side of the membrane process. In other words, MD is based on the phenomenon in which pure water in the vapor state can be extracted from aqueous solutions, with the vapor passing through the membranes pores. The temperature difference leads to a vapor pressure difference across the membrane. Due to the hydrophobic nature of the membrane, only vapor can pass through the membrane and not the liquid solution being distilled.

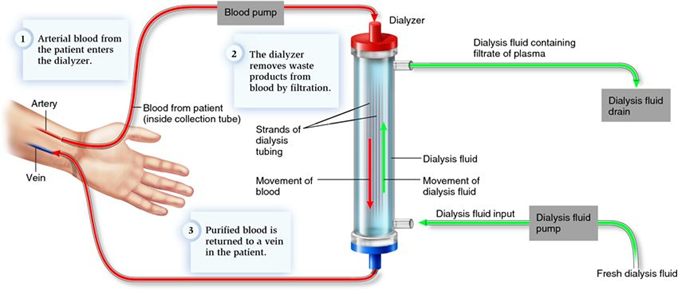

Hemodialysis

Hemodialysis is a process of purifying the blood of a person whose kidneys are not working normally. In the other word, hemodialysis is a treatment process that directly removes the pathogenic substance or toxic substance from the patients’ blood by means of extracorporeal circulation equipment. To achieve this purpose, thousands of porous hollow fiber membranes are fitted into a single membrane module commonly known as hemodialyzer. In general, the heart of the hemodialysis machine is the hemodialyzer, where semipermeable membranes are arranged in the middle, serves as membrane contactor to form separate adjacent paths for blood and dialysate.

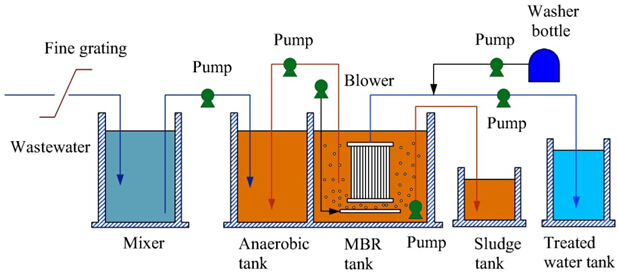

Membrane Bioreactors (MBR):

The combination of biological processes with membrane separation is one of the newest rapidly growing sewage treatment technologies in the industry known as Membrane bioreactor (MBR). Low-pressure membranes (such as microfiltration or ultrafiltration) are commonly used in MBRs. The common filtration systems have a sewage aeration unit, secondary clarifier and possibly third-order filters. When wastewater treatment uses aerobic or anaerobic biological processes, system stability and refined water quality are usually dependent on the remaining sludge separation at the end of the process. Today, membrane bioreactors are used to treat various types of wastewater, such as municipal sewage, high-organic wastewater and heavy wastewater. There are two types of membrane systems that can be used in MBRs: First, cartridges inside the tubing with vacuum propulsion, which are designed to be installed inside the membrane bioreactor. Second, submerged membrane technologies use hollow fiber membranes or flat plates. Due to the need for low pressure (vacuum force) to be easier to operate and adapt to changes in the types of solids contained in active sludge bioreactors and lower final cost, especially in utility installations, the most common uses are membrane bioreactors.

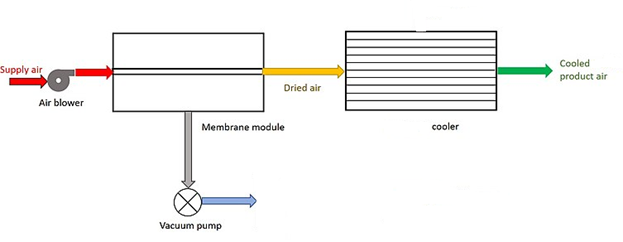

Membrane air conditioning

Membrane air conditioning is a hybrid membrane system. It consists of two separate units which are couple together to form an air conditioning system. The first unit is used to remove the water vapor from an incoming humid warm air stream without changing its temperature, i.e., through a vapor membrane separation module. A high permeance along with a high H2O/Air selectivity are the critical performance parameters. The required driving force is supplied by the transmembrane pressure. The second unit is a membrane contactor cooling the air stream to a comfort level. Membrane contactor uses the fact that water will absorb a relatively large amount of latent heat in order to be evaporated. The temperature of dry air can be dropped significantly through the phase transition of liquid water to water vapor. This can cool air using much less energy than the conventional refrigeration systems.

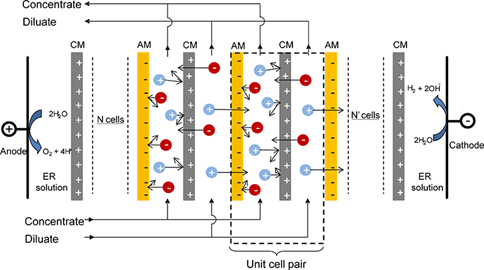

Electrodialysis (ED)

Electrodialysis (ED) is a type of technology that arranges ion-exchange membranes alternately in a direct current field. As it is known there are at least five major elements complementary for ED applications: (1) direct current supply, which proves effective to reinforce ion migration; (2) electrodes, where the oxidation/reduction reactions occur to realize the transformation from ionic conduction to electron conduction and thus provide the original driving force for ion migration; (3) ion exchange membranes, the key components which permit the transport of counter ions and block the passage of co-ions; (4) solvents, which make a media for ion transport by filling the space between the electrodes and membranes; (5) electrolyte, the current i.e. electron carrier between cathode and anode.